Once the roof was completed, we started on interior projects including electrical, plumbing, heating, etc. Although we were still waiting for our windows to arrive, the house was still pretty dry, so we started the electrical. This was in October 2014.

One of the highlights of this project was seeing the first light turned on (below), on November 7, 2014.

|

| Steve and his Dad admiring the first light in the house! |

The first challenge with electrical was ordering all the supplies. It was not easy to know how much of each item to order, and which kind, so we consulted with my cousin Nathan, who is a licensed electrician, and he knew exactly what we needed! We got our supplies ordered, and then a huge pile of supplies arrived to start the electrical. Thank you for your help Nathan!

Electrical work is very detailed, intricate and time-consuming. We were really fortunate to have help from Steve's Dad who happily tackled this project pretty much from start to finish.

Because we used ICF to build the house, the electrical work was not traditional, especially in the exterior walls. Since the walls are concrete with insulation inside, channels had to to be cut in the insulation to be able to run all the electrical wires. After using multiple tools to do this, the skill saw ended up being the best solution. By the end of the day, Mike would be covered with white insulation from the ICF blocks!

Here is a close-up of one of the boxes. This box happens to be for our speaker wires, but you can see how it's recessed into the insulation. The boxes are attached to the plastic studs in the ICF blocks. All the wires were labeled and neatly wound until we were ready for switches and outlets.

We have over 40 recessed lights in the house, including the living room, hallways, bathrooms and exterior. We used Halo 5" Air-Tight IC recessed lights.

|

| Sloped ceiling recessed lights in the living room. |

|

| View from above recessed lights in the hallway. |

Outlets were installed to code. There are lots of outlets - to guess, there is at least one outlet every 10' of wall, usually closer depending on the room.

The electrical work on the interior walls could be done traditionally with boxes mounted to the 2x4 framing.

And alas, the first light switch!

And the first light! We were pretty excited! (Notice, no windows yet!)

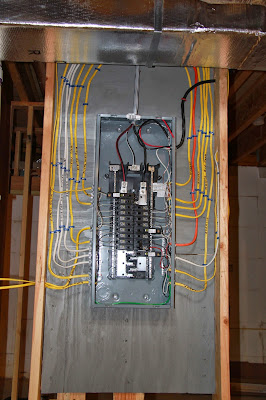

We have three electrical panels. The main panel is 200 Amp and is located in the garage - this is where the electrical service from the road is connected. In the photo below, you can see where the electrical service comes in through the wall and enters into the panel. The smaller box on the left is for the generator.

From there, we have two 100 Amp sub-panels, both in the utility room in the basement. Since two panels were necessary, one was wired specifically to be used with the generator. Only items that were to run via generator were put on this panel. Everything else went on the other panel.

In the photo below, all the rough electric has been completed. You can see all the boxes in the walls, lights and wiring in the kitchen island.